Specialist Lift Engineer Course: Educating for Leading Lift Repair Companies Near Me

Specialist Lift Engineer Course: Educating for Leading Lift Repair Companies Near Me

Blog Article

Important Aspects to Take Into Consideration for Lift Upkeep

When it comes to the risk-free and reliable procedure of lifts, taking into consideration necessary maintenance variables is paramount. It is critical for constructing managers and upkeep employees to remain ahead of these aspects to support the lift's efficiency requirements and compliance demands.

Regular Inspection Schedules

Performing routine evaluations not only improves the total performance of the elevator yet also plays an important role in adhering to safety and security policies and sector standards. It guarantees that the lift runs efficiently, reducing the risk of unforeseen break downs that can hassle passengers or concession safety. Furthermore, routine assessments add to extending the lifespan of the lift tools, eventually decreasing maintenance expenses and downtime.

To improve the inspection procedure, numerous structure proprietors companion with qualified elevator upkeep business that concentrate on carrying out comprehensive assessments and offering punctual maintenance services. By focusing on normal assessment schedules, stakeholders can copyright the safety, reliability, and efficiency of their elevator systems.

Appropriate Lubrication Techniques

Efficient lubrication techniques are vital for preserving the optimal efficiency and long life of elevator components. Appropriate lubrication strategies play a crucial role in stopping damage on relocating components, minimizing friction, and ensuring smooth operation of the elevator system. When it involves elevator upkeep, using the right lubes in the right amounts at the recommended intervals is crucial to decreasing and preventing expensive repair services downtime.

To make certain proper lubrication, elevator specialists should comply with maker standards pertaining to the kind of lubricant to be used for specific components such as bearings, equipments, and overview rails - lift repair companies near me. Over-lubrication can attract dust and debris, leading to component breakdowns, while under-lubrication can create boosted rubbing and early wear. Routinely scheduled lubrication maintenance should be consisted of in the general elevator maintenance strategy to keep the system running successfully and securely

Keeping An Eye On Tear and wear

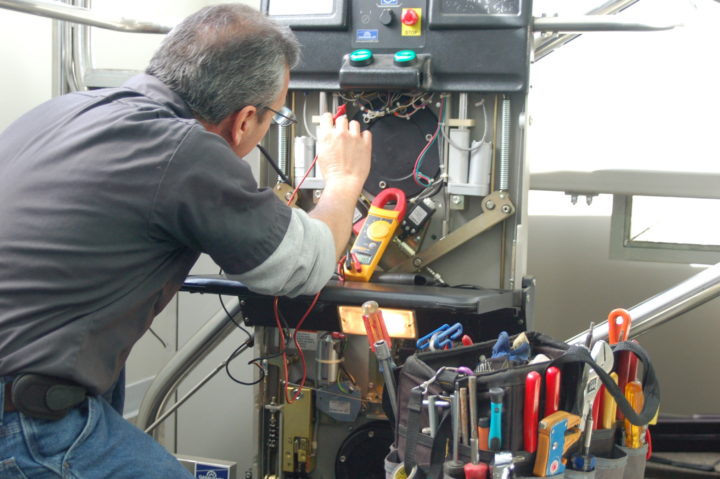

Proper lubrication strategies are indispensable in promoting the early detection and monitoring of deterioration on lift elements. Regular lubrication helps reduce rubbing in between moving components, protecting against too much wear and prospective break downs. Checking wear and tear goes past just lubrication. Lift maintenance see this page employees ought to conduct regular evaluations to recognize indications of wear on crucial components such as ropes, sheaves, guide rails, and bearings. These examinations may entail visual checks, gauging wear limitations, and making use of diagnostic devices to examine the problem of crucial components. Additionally, maintaining detailed upkeep records can aid in tracking the wear patterns of elevator parts in time, enabling predictive upkeep preparation. By closely checking wear and tear, upkeep groups can deal with problems proactively prior to they rise into expensive fixings or unexpected downtime, making sure the effective and secure procedure of the elevator system.

Security Conformity Checks

Conducting extensive safety compliance checks is vital in ensuring the lift system satisfies all regulatory standards and functional demands. These checks additionally include verifying that the lift's capacity restrictions, rate, and emergency communication systems are in line with safety requirements. Additionally, adherence to safety and security compliance checks can prevent mishaps, reduce responsibility threats for building proprietors, and prolong the lifespan of the lift system.

Emergency Action Planning

Due to the vital importance of security compliance sign in maintaining elevator systems, a robust emergency situation feedback planning method is vital to swiftly and properly address visit homepage unexpected events. lift maintenance company. Emergency action preparation for elevators involves positive actions to make sure the safety and security of passengers and maintenance employees in case of emergencies such as power outages, entrapments, or mechanical failures

Trick parts of an effective emergency situation feedback strategy include establishing clear communication methods, providing regular training to personnel on emergency situation treatments, keeping up-to-date emergency get in touch with listings, description and carrying out regular drills to practice reaction actions. Furthermore, it is vital to have designated employees in charge of coordinating emergency reactions and making sure that needed tools, such as emergency situation lights and interaction tools, remain in functioning order.

Verdict

In verdict, it is crucial to focus on normal examination timetables, correct lubrication strategies, keeping an eye on deterioration, security compliance checks, and emergency response preparation for lift maintenance. By executing these vital elements, building proprietors can make certain the safety and security and effectiveness of their elevators, ultimately reducing the threat of crashes and malfunctions. Regular maintenance practices are essential for lengthening the life expectancy of elevators and ensuring the health of people who depend on them for transportation.

Routinely scheduled lubrication upkeep should be included in the total elevator upkeep plan to keep the system running successfully and safely.

Lift maintenance personnel need to carry out regular assessments to identify indicators of wear on essential parts such as ropes, sheaves, guide rails, and bearings. In addition, keeping detailed upkeep records can help in tracking the wear patterns of elevator elements over time, allowing for predictive upkeep planning. By closely checking wear and tear, maintenance groups can address problems proactively before they rise into pricey repairs or unanticipated downtime, making certain the efficient and secure procedure of the lift system.

Report this page